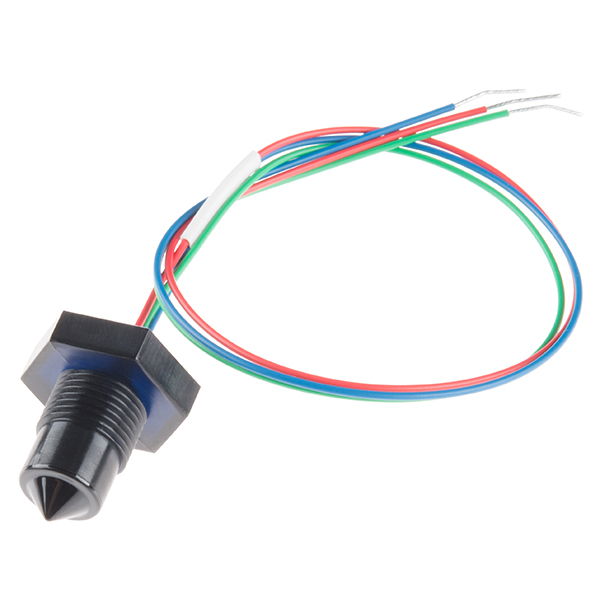

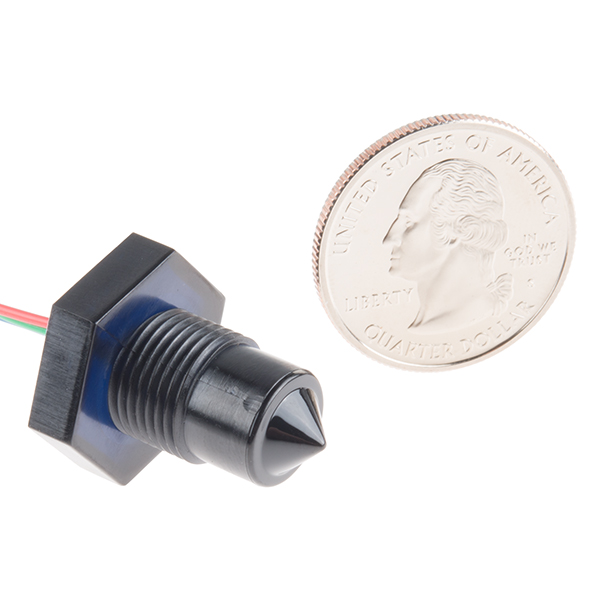

The SST Liquid Level Sensor provides single point liquid detection via a TTL compatible push/pull output. This optical liquid level sensor features a miniature design that allows for installation in areas where space is limited. Thanks to its minimal solid state design, this sensor has been built without moving or mechanical parts that can be jammed and stop working.

An infra-red LED and phototransistor accurately positioned at the base of the sensing tip ensure good optical coupling between the two when the sensor is in air. When the sensing tip is immersed in liquid, the infra-red light escapes from the cone, causing a change in the amount of light present at the phototransistor, which makes the output change state.

- Supply Voltage: +4.5 Vdc to +15.4Vdc

- Output Current: 100mA

- Temperature Range: -25 to +80⁰C

- Polysulphone Housing Tip

- M12 threaded connector (mounted from outside)

SST Liquid Level Sensor Product Help and Resources

Core Skill: Programming

If a board needs code or communicates somehow, you're going to need to know how to program or interface with it. The programming skill is all about communication and code.

Skill Level: Rookie - You will need a better fundamental understand of what code is, and how it works. You will be using beginner-level software and development tools like Arduino. You will be dealing directly with code, but numerous examples and libraries are available. Sensors or shields will communicate with serial or TTL.

See all skill levels

Core Skill: Electrical Prototyping

If it requires power, you need to know how much, what all the pins do, and how to hook it up. You may need to reference datasheets, schematics, and know the ins and outs of electronics.

Skill Level: Rookie - You may be required to know a bit more about the component, such as orientation, or how to hook it up, in addition to power requirements. You will need to understand polarized components.

See all skill levels

Comments

Looking for answers to technical questions?

We welcome your comments and suggestions below. However, if you are looking for solutions to technical questions please see our Technical Assistance page.

Customer Reviews

3.4 out of 5

Based on 5 ratings:

1 of 1 found this helpful:

Not worth Using

The Sensors form, small simple installation make it practical for limited space application, the issues was consistency. The singles it sends back jumps all over the place. It is supposed to be a simple high low switch but the data sheet says PWM, so I tried measuring pulse too but found the device gives faulty readings. I thought it was maybe a defective sensor so I tried a second one I had and same thing. Ended up having to use another method to detect coolant levels. Would not recommend using in any project that needs consistent results.

The issue may be occurring when liquid splashed up onto the sensor. I'd recommend contacting our tech support team. They should be able to figure out the best course of action.

2 of 2 found this helpful:

Excellent liquid level sensor

Great experience using 50 (fifty) of these sensors for an electronics/computer education program. Water level sensing was a critical component of the program, and I tried several different technologies, including eTape and float sensors. I found no other sensors to be reliable. These sensors are compact, rugged, have no moving parts, and provide a simple interface. All 50 did exactly what they were supposed to do.

2 of 2 found this helpful:

It works great for my application!

I'm using this sensor on a top-up system for an aquarium of mine. Because the water level drops slowly due to evaporation, I don't have to worry about water droplets disrupting the signal, which another reviewer has stated can happen. The valuable part of the optical switch for me is that it's impervious to disruption by snails. The snails can jam up magnetic float switches and cause them to stick in the fill position which can be disastrous. The sensor is indeed very sensitive, so waves and ripples in the water can disrupt it easily. I used a Resistor-Capacitor network to groom the signal for a Schmitt trigger to compensate for this. Overall, I love this sensor!

2 of 3 found this helpful:

Too sensitive for me,

with just a drop of water on the end of it, it changes states. cost is to high as well.

Great!

I just Finished a school project and it served its purpose well. Me and my friend just used it as a true or false statement in our code and it worked great! The sensor was sensitive to the water but served our panel demo well. 10/10

You should mention that this sensor is on-off, either it's in the liquid or it isn't -- it doesn't give a level value.

Don't be silly, this is definitely a liquid level sensor. It even has an integrated analog to digital converter with 1-bit resolution!

This looks entirely sealed, (i.e. there is no passage where the water interferes inside), so I presume it will work sideways? I have a side mount application....

It would have been nice if you guys included the o-ring and nut sold by the manufacturer

To clarify a bit on the product. Think of this as an alternative to a standard float switch. There is a price difference there, but in most cases, it provides a more reliable way of sensing when a liquid has reached a certain point or level in the container it is in. Arbiag is correct, this won't give you a variable reading.

The data sheet notes sensitivity to chlorine. I wonder if this would be suitable for a swimming pool. If it's light-based, I presume changing daylight levels might skew readings a bit.

The data sheet mentions that chlorinated solvents will attack the material the sensor is made of. The minuscule amount of chlorine you find in pool water should not be an issue though. I have not tested this sensor so I can't comment on daylight skewing the readings. It would probably be a good idea to keep this out of sunlight to ensure proper operation.

This is much more expensive than a standard moisture sensor that uses two probes and measures conductivity - does it provide something that those don't? Also, if this sits in dirty water will it still work since the IR cone might be optically blocked?

So, if I intend to read the level of fuel in a deposit, I should use several sensors on a side mount, in order to obtain the variation during time. Is it correct? It sounds very good for the price!

Could this be turned upside down and used as a rain sensor? Or would daylight confuse it?

I want a liquid level sensor that works with (near) boiling water. This one doesn't fit as it is only suitable up to 80C. Even if it did I doubt it would last.. I've used an assortment of floats, pressure sensors, optical sensors, etc.. I'm currently using my own hybrid sensor (basically a resistance meter), while a lot better than anything I've been able to source so far, still has it's limitations. So I'm curious if anyone else has a good idea?

Pretty sure this is what Keurig does to measure levels in the boiler (re: resistance meter). There are typically two small, metal rods that extend from the top of the boiler and point down towards the heating coil. I'd imagine their primary concerns were high temperatures and longevity, so it sounds like you're on the right track.